Key benefits

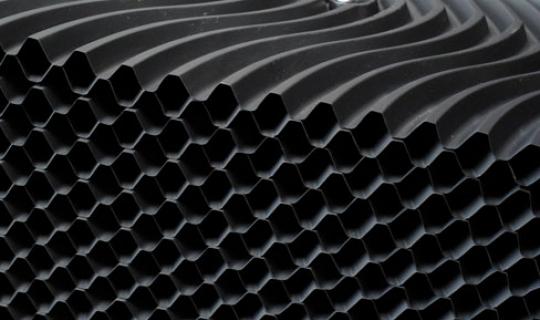

- Unique sheet design

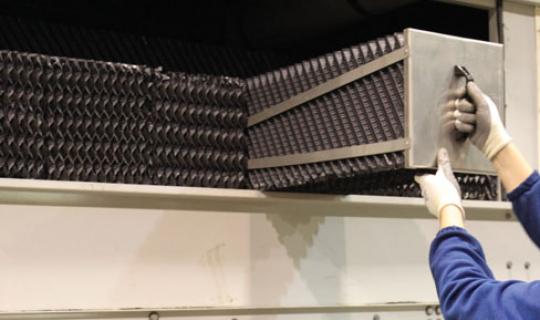

- Easy cleaning

We design, develop and manufacture most of our fill types in house to ensure the highest quality. Our R&D engineers subject the fill to all kinds of environmental and operational conditions like

- influence of air and spray water flow, pressure and distribution patterns

- installation and maintenance procedures to guarantee original performance and operational safety.

That's why you should choose for original BAC fill when replacing the heart of your cooling tower. Check in the table below what fill you need for replacement or upgrading your BAC cooling equipment.

| BAC product type | Replacement fill | Upgrade fill |

|---|---|---|

| VXT | BACount bundles | |

| VTL-E | BACount bundles | |

| TXV | BACross, BACross bundles |

BACross bundles |

| FXT | BACross | |

| S3000 previous generation | BACross, BACross bundles |

BACross bundles, VersaCross |

| S3000D | BACross II | |

| PTE | Versapak | |

| IMT | Versapak, FRP fill |

FRP fill |

| RCT | Versapak, FRP fill |

FRP fill |

| FCT | Versapak | |

| FXV (cooler) | BACross, BACross bundles | BACross bundles |

| FXVE (cooler) | BACross II | |

| CXV (condenser) | BACross, BACross bundles | BACross bundles |

| CXVE (condenser) | BACross II | |

| FXV-D (cooler) | BACross II | |

| CXV-D (condenser) | BACross II |

BAC offers for all cooling tower types high temperature fill alternatives, depending on the type and the requirements

- in CPVC instead of PVC fill material

- in polyprop bundles instead of PVC bundled sheets

Check for high temperature applications also the need for change of other components. Contact your local BAC representative for more information.

Want to know more about BAC fill? Contact your local BAC representative for more information.