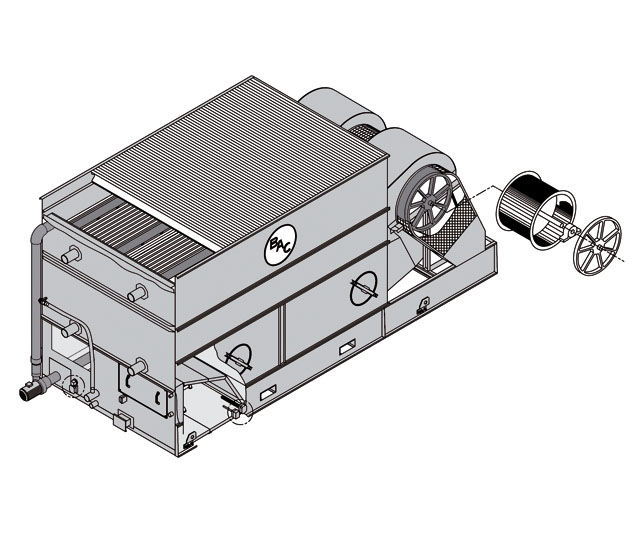

1. Scelta di materiali

- Acciaio zincato a bagno di forte spessore viene utilizzato per i pannelli dell'unità esterna e gli elementi strutturali che presentano la protezione anti-corrosione Baltiplus.

- L'esclusivo rivestimento ibrido Baltibond® è disponibile come opzione. Un rivestimento polimerico ibrido che assicura una vita utile più lunga, pre-applicato a tutti i componenti in acciaio zincato a bagno dell'unità.

- Acciaio inox opzionale per pannelli ed elementi strutturali di tipo 304L, oppure tipo 316L per applicazioni estreme.

- Oppure l'alternativa economica: una vasca per l'acqua fredda in acciaio inox per il contatto con l'acqua. I componenti principali e la vasca stessa sono in acciaio inox. Gli altri elementi sono protetti dal rivestimento ibrido Baltibond®.

2. Elemento di scambio termico

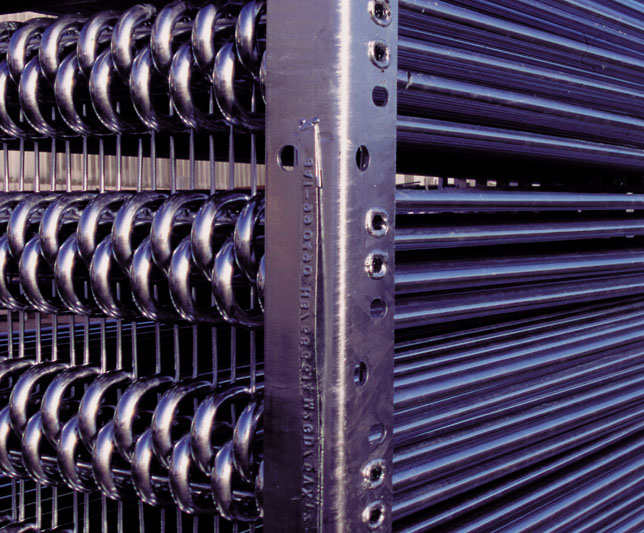

Batteria di scambio principale

Batteria di scambio principale

- La batteria è costruita con tubi in acciaio di prima qualità, ed è zincata a bagno dopo la fabbricazione. Progettata per il libero drenaggio del fluido e una pressione d'esercizio massima di 10 bar, conformemente alla PED. Testata ad aria compressa a 15 bar

- Tutte le batterie zincate a bagno e in acciaio inox sono fornite con protezione da corrosione interna (ICCP) di BAC per assicurare una protezione da corrosione interna ottimale e garantire la qualità.

Opzioni per la batteria: batteria in acciaio inox tipo 304L o 316L.

Batteria alettata opzionale

- La batteria alettata a secco è costruita con un minimo di 4 circuiti di tubi di rame sfalsati con alette in lamiera di alluminio.

- Progettato per il drenaggio libero del fluido e per una pressione di esercizio massima di 10 bar secondo la PED. Testato pneumaticamente a 15 bar.

- In combinazione con un pacchetto di controllo del flusso comprendente una valvola a 3 vie, un sensore di temperatura e tubazioni.

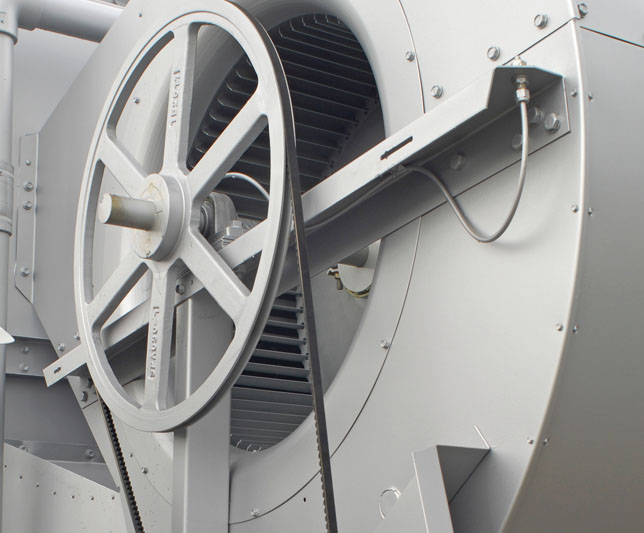

3. Sistema di movimentazione dell'aria

- Con ventilatore centrifugo a motore e azionamento a cinghia trapezoidale. È possibile rimuovere facilmente l'intera base del motore per un corretto tensionamento della cinghia per garantire un allineamento della cinghia costantemente corretto. Insieme ai cuscinetti dell'albero del ventilatore per servizi heavy duty, assicura l'efficienza di esercizio ottimale per tutto l'anno.

- I ventilatori centrifughi sono curvati in avanti e quasi silenziosi. Superare la pressione statica esterna! Utilizzare attenuatori acustici e lavori di canalizzazione ecc. per l'aspirazione/scarico dell'aria senza perdita di prestazione termica!

- Gli eliminatori di gocce, sono di plastica resistente ai raggi UV; sono esenti da marcescenza, deterioramento o decomposizione e le prestazioni sono testate e certificate da Eurovent. Vengono assemblati in sezioni maneggevoli e facilmente rimovibili, che assicurano l'accesso ottimale.

4. Sistema di distribuzione acqua

- Una testata e rami di spruzzatura con ampi ugelli in plastica non intasabili, fissati con gommini in gomma.

- Una sezione di raccolta dell'acqua nebulizzata con:

- vasca inclinata a secco con porte di accesso circolari

- bacino dell'acqua umida fuori dal flusso d'aria, compreso il filtro anti-vortice facile da sollevare, trucco, porte d'accesso rettangolari.

- Pompa di nebulizzazione centrifuga ad accoppiamento diretto con guarnizioni in bronzo, con motore di tipo totalmente chiuso e raffreddato ad aria (TEFC) alla fine del collegamento dell'unità. Linea di spurgo con valvola di calibrazione, che collega la mandata della pompa al troppo pieno.

- Il pacchetto elettrico di controllo del livello dell'acqua mantiene costante il livello dell'acqua nel pozzetto dell'acqua fredda indipendentemente dalle variazioni del carico di raffreddamento e dalle variazioni di pressione dell'acqua di alimentazione.

Desideri conoscere maggiori dettagli costruttivi sulle unità HFL? Puoi rivolgerti al rappresentante BAC di zona..