Key benefits

- Lowest energy consumption and total cost of ownership

- Year round reliable operation

- Ideal replacement unit with certified thermal performance

Lowest energy consumption and total cost of ownership

- Evaporative cooling for system-wide energy saving at lower operating temperatures.

- The highly efficient OptiCoil™ System increases thermal performance up to 30% for the same coil volume lowering the installed fan power by up to 50%.

- Elimination of potentially excessive operating costs. PFI is Eurovent-CTI certified for both water and glycol. This guarantees thermal performance and it eliminates field thermal performance testing costs.

- System pump energy savings obtained through shorter coil circuits resulting in lower coil pressure drops.

- Savings on maintenance and water treatment because the closed loop in PFI cooling towers ensures a contaminant-free cooling circuit.

- Lower installed costs. PFI has a lower weight, reducing structural and vibration isolation costs. Less glycol is required to achieve the same or higher heat transfer.

- Water and chemical savings up to 33% because Baltibond® Hybrid Coating allows higher cycles of concentration.

Year round reliable operation

- Trouble free process operation - The closed loop in PFI cooling towers protects the process fluid and equipment from external contaminations.

- The thermal performance of PFI closed circuit cooling towers is tested and certified by Eurovent.

- For extremely cold weather operation, switch off the spray system during periods of reduced load and operate dry.

- Optimal thermal performance through lifetime. Lab tests have proven that the OptiCoil System reduces scale formation on the coil.

- Minimum maintenance and downtime- Complete and easy access to all critical components, including coil.

- Easy-clean and easy-inspect PFI towers reduce hygiene risks from bacteria (e.g. Legionella) or biofilm inside.

- Self-cleaning cold water basin sloping towards drain, to prevent sediment build up.

- Combined inlet shields block sunlight to prevent biological growth in the tower, filter the air and stop water splashing outside.

Ideal replacement unit with certified thermal performance

- Same or higher capacity. Ideal like-for-like solution, performing per published ratings. The PFI is independently Eurovent-CTI certified for various process fluids.

Low noise

- A variety of fans is available to offer the perfect solution for every sound challenge.

- Water silencers achieve noise levels close to those of crossflow towers. Water silencers come always with Whisper Quiet fans.

- Factory designed, tested and rated sound attenuation is available on the discharge for further noise reduction.

Easy to maintain

- The PFI closed circuit cooling tower is easier to maintain than other induced draft counterflow cooling towers.

- Optional coil inspection hatches allow complete and easy access to heat transfer section

- BranchLok™ water distribution - each branch removable for easy cleaning.

- Combined inlet shields for easy no-tool removal.

- Motor adjusters: externally accessible and locking wrench for easy motor alignment and belt tensioning.

- Full cold water basin access when removing the combined inlet shields.

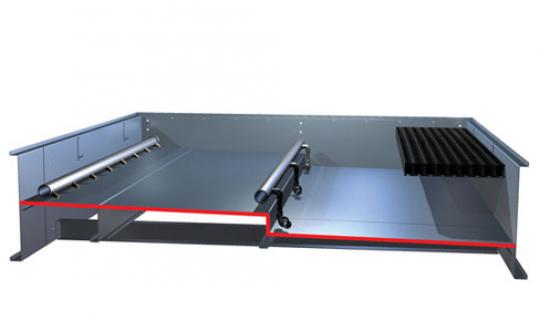

- Fans easy accessible via sliding access door.

- Optional clean out port helps remove silt and sludge from the cooling tower basin.

- Removable suction strainer anti-vortex hood.

Ship and install PFI easily

- Guide pins mean swift PFI cooling tower on-site assembly. The guide pins help reduce section assembly time by up to 75 %!

- Compact PFI footprint – perfect for confined spaces.

- Container shipment often possible!

Interested in the PFI closed circuit cooling tower for cooling your process fluid? Contact your local BAC representative for more information.